ESO6

ES12

ES06-01

ES12-01

ES06/ES12

by Nachi

High speed handling

- Super rigid arm and servo control give this horizontal articulated scara robot fast, high-accuracy operations.

- High-speed operations meet demand to support a wide range of fields, from the handling of small parts to high precision assembly work.

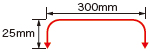

Cycle time of standard arch motion

ES06 : 0.29sec

ES12 : 0.30sec

Prevent cable interference

- Hands with internal passage for wiring available to be mounted on tip of arm.

- Wiring and piping can be run internally to the point where the hand is attached.

- Minimize area in which robot cables interfere with peripheral equipment.

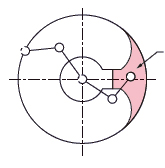

Fully utilize installation space

- Possible to access entire periphery with swivel operation range.

- Improves flexibility when considering robot layout.

Specification

ES06-01

| Max. reach | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|

| 350mm | 125 | R350 | R142 | 210 | R253 | 220 | R174 | 342 |

| 450mm | 225 | R450 | R135 | 337 | ||||

| 550mm | 325 | R550 | R191 | 160 | R244 | 172 | R197 |

| Vertical stroke | J | K | L | M |

|---|---|---|---|---|

| 200mm | 200 | 133 | 798 | 386 |

| 340mm | 340 | -7 | 938 | 526 |

ES12-01

| Max. reach | A1 | A2 | B | C | D | E | H |

|---|---|---|---|---|---|---|---|

| 550mm | 225 | 325 | R550 | R191 | 145 | 240 | R295 |

| 700mm | 375 | R700 | R216 | ||||

| 850mm | 525 | R850 | R278 | 153° | — | — |

| Vertical stroke | F | G |

|---|---|---|

| 350mm | 1080 | 350 |

| 450mm | 1180 | 450 |

Robot specifications:ES06

Robot model

- Payload

- Maximum reach (input the rst two digits): 550, 450, 350mm

- Vertical stroke (shows rst two digits): 200, 340mm

- Version

| Robot model | ES06- 3520-01 |

ES06- 3534-01 |

ES06- 4520-01 |

ES06- 4534-01 |

ES06- 5520-01 |

ES06- 5534-01 |

|

|---|---|---|---|---|---|---|---|

| Structure | Horizontal articulation | ||||||

| Number of axes | 4 | ||||||

| Drive system | AC servo system | ||||||

| Brake | Axes 1, 2, and 4: No brakes Axis 3: With brake | ||||||

| Max. operating envelope |

J1 | ±2.97rad (±170°) | |||||

| J2 | ±2.53rad (±145°) | ||||||

| J3 | 200mm | 340mm | 200mm | 340mm | 200mm | 340mm | |

| J4 | ±6.28rad (±360°) | ||||||

| Max. velocity *4 | J1 | 6.98rad/s (400°/s) | |||||

| J2 | 11.69rad/s (670°/s) | ||||||

| J3 | 2400mm/s | ||||||

| J4 | 43.63rad/s (2500°/s) | ||||||

| Payload(Max.) | 3kg (6kg) | ||||||

| Maximum pressing force of third axis |

165N *7 | ||||||

| Max. allowable moment of inertia *1 |

0.12kg·m2 (0.01kg·m2 rated) | ||||||

| Position repeatability |

X and Y combined |

±0.012mm | |||||

| J3 (Z) | ±0.01mm | ||||||

| J4 (θ) | ±0.004° | ||||||

| Max. reach | 350mm | 450mm | 550mm | ||||

| Air piping | Primary:Ø6 x 2 Secondary:Ø4 x 8 *5 | ||||||

| Application wirings | Hand: 8 points input/8 points output (20 lines) Dedicated signal line for multipurpose hand (2 lines + 2 power lines) 1 Ethernet cable <100BASE-TX> (8 lines) *6 |

||||||

| Installation | Floor mount | ||||||

| Ambient conditions |

Ambient temperature : 0 |

||||||

| Environmental conditions *3 | IP20 | ||||||

| Robot mass | 36kg | 37kg | |||||

Robot specifications:ES12

Robot model

- Payload

- Maximum reach (input the rst two digits): 550, 700, 850mm

- Vertical stroke (shows rst two digits): 350, 450mm

- Version

| Robot model | ES12- 5535-01 |

ES12- 5545-01 |

ES12- 7035-01 |

ES12- 7045-01 |

ES12- 8535-01 |

ES12- 8545-01 |

|

|---|---|---|---|---|---|---|---|

| Structure | Horizontal articulation | ||||||

| Number of axes | 4 | ||||||

| Drive system | AC servo system | ||||||

| Brake | Axes 1, 2, and 4: No brakes Axis 3: With brake | ||||||

| Max. operating envelope |

J1 | ±2.97rad (±170°) | |||||

| J2 | ±2.53rad (±145°) | ±2.67rad (±153°) | |||||

| J3 | 350mm | 450mm | 350mm | 450mm | 350mm | 450mm | |

| J4 | ±6.28rad (±360°) | ||||||

| Max. velocity *4 | J1 | 7.33rad/s (420°/s) | 4.89rad/s (280°/s) | ||||

| J2 | 7.85rad/s (450°/s) | ||||||

| J3 | 2800mm/s | ||||||

| J4 | 41.89rad/s (2400°/s) | ||||||

| Payload(Max.) | 3kg (12kg) | ||||||

| Maximum pressing force of third axis |

200N *7 | ||||||

| Max. allowable moment of inertia *1 |

0.3kg·m2 (0.025kg·m2 rated) | ||||||

| Position repeatability |

X and Y combined |

±0.012mm | ±0.015mm | ||||

| J3 (Z) | ±0.01mm | ||||||

| J4 (θ) | ±0.005° | ||||||

| Max. reach | 550mm | 700mm | 850mm | ||||

| Air piping | Primary:Ø6 x 2 Secondary:Ø6 x 8 *5 | ||||||

| Application wirings | Hand: 8 points input/8 points output (20 lines) Dedicated signal line for multipurpose hand (2 lines + 2 power lines) 1 Ethernet cable <100BASE-TX> (8 lines) *6 |

||||||

| Installation | Floor mount | ||||||

| Ambient conditions |

Ambient temperature : 0 |

||||||

| Environmental conditions *3 | IP20 | ||||||

| Robot mass | 65kg | 67kg | 69kg | ||||

1[rad] = 180/π[°], 1[N·m] = 1/9.8[kgf·m]

( * ) Explosion-proof is not available.

(*1) Note that maximum allowable moment of inertia varies according to load conditions on the wrist.

(*2) Permitted height is not higher than 1,000m above sea level. If used in higher place, permitted temperature is affected by height.

(*3) Fluids that cause the deterioration of sealants, such as gasoline-based cutting

uids, chlorine, alkali, acids, and organic solvents, cannot be used.

(*4) The maximum velocity in the chart is a maximum value. The maximum value may change depending on work programs and load conditions of the wrist.

(*5) Secondary Ø4 piping is possible with solenoid valve (option).

(*6) Possible to use 8 lines for LAN wiring as spare wires, too.

(*7) Downward pressing force that is possible on tip of load when maximum load is mounted, and axis 1, axis 2, and axis 4 are static. Use at values below those noted here.

Also, an overload error occurs if pressure is applied for a long period of time. Use under conditions in which errors do not occur.

Also, an overload error occurs if pressure is applied for a long period of time. Use under conditions in which errors do not occur.